Medical extrusion is revolutionizing the way catheters are manufactured, allowing for enhanced performance and precision. As the demand for customized medical devices grows, catheter custom extrusion has emerged as a critical process that ensures the adaptability and functionality of these essential tools.

Understanding Medical Extrusion

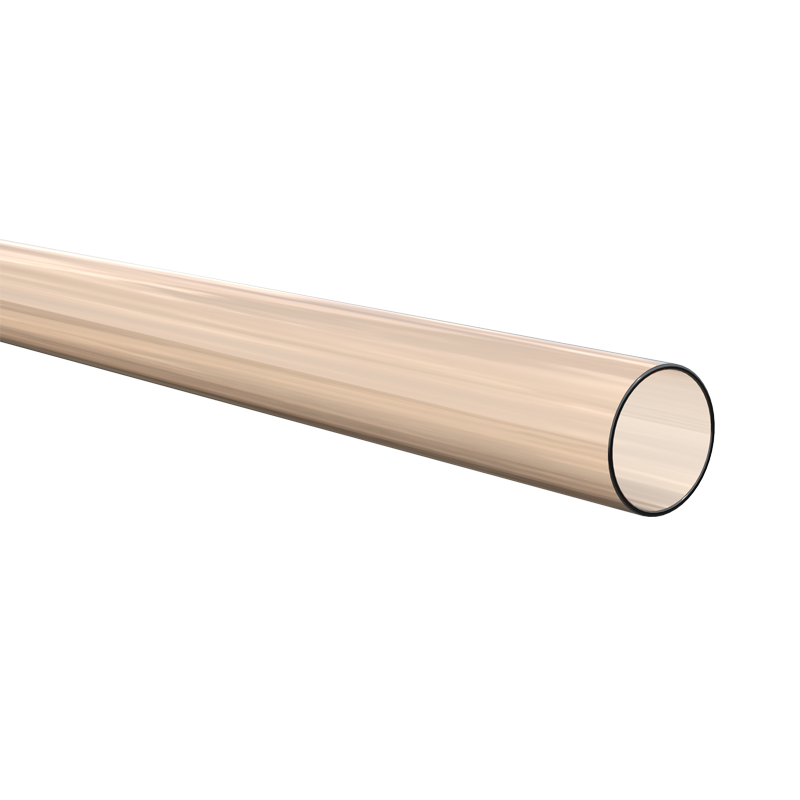

Medical extrusion is a manufacturing technique that involves shaping materials into specific profiles through a die. This process is particularly significant in the production of catheter components, where precise dimensions and material properties are paramount. Catheter custom extrusion enables manufacturers to create tubing that meets the exact specifications required for various medical applications, ensuring both reliability and effectiveness in patient care.

The Advantages of Catheter Custom Extrusion

One of the primary benefits of catheter custom extrusion is the ability to tailor the physical properties of the tubing. For instance, jMedtech’s ToughFlex™ extruded PTFE liner provides superior flexibility while maintaining size accuracy. This precision is essential for catheters, which must navigate complex bodily pathways without compromising performance. Custom extrusion allows manufacturers to adjust wall thickness, diameter, and material characteristics to suit specific medical needs.

Innovations in Extrusion Technology

Advancements in extrusion technology have significantly improved the capabilities of catheter manufacturing. Sophisticated equipment and techniques enable the production of thin wall tubing that is both lightweight and durable. By leveraging these innovations, companies can enhance the usability of catheters, ultimately leading to better patient outcomes. Catheter custom extrusion not only facilitates design flexibility but also streamlines the production process, reducing lead times and costs.

Enhancing Medical Device Quality Through Custom Solutions

The role of catheter custom extrusion in the medical field cannot be overstated. As manufacturers like jMedtech continue to push the boundaries of extrusion technology, the potential for creating more effective and reliable catheters expands. Emphasizing customized solutions will drive innovation and improve the quality of medical devices, ultimately benefiting healthcare providers and patients alike.