In automotive manufacturing, achieving “Class A” surface finishes is paramount, as they are essential for both aesthetic quality and functional performance, directly influencing aerodynamics and assembly efficiency. A large scale resin 3D printer is uniquely engineered to deliver this superior finish at production-capable sizes—a key advantage unattainable by desktop or filament-based systems.

The Advantage of Photopolymerization over Extrusion

The foundation of superior surface quality lies in the layering technology. Stereolithography employs a UV laser to precisely cure liquid photopolymer resin. This process facilitates molecular-level bonding between layers, resulting in a naturally smooth, isotropic, and non-porous surface structure. Consequently, large-scale components such as automotive bumpers or full-size prototypes can be paint-ready directly off the print platform, substantially reducing labor-intensive post-processing like sanding and priming.

Engineering Stability for Massive Components

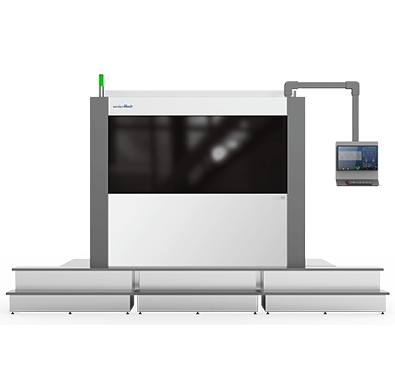

Achieving a flawless finish on meter-scale parts demands exceptional mechanical stability and precision. As a premier industrial 3D printer manufacturer, UnionTech addresses this challenge through robust hardware design. Systems like the UnionTech RSPro 2100 utilize a granite-based recoater frame, offering inherent thermal stability and superior vibration damping. This ensures the consistent application of resin layers as thin as 50 microns across the entire large build area, effectively preventing surface imperfections like rippling.

Core Benefits for Modern Production

Implementing UnionTech’s large-format industrial SLA printers provides distinct strategic advantages: seamless, one-piece construction eliminates the weak points and visual seams of assembled parts; a finely controlled laser spot captures intricate textures and sharp details beyond the reach of traditional CNC tools; and the excellent as-printed finish dramatically accelerates time-to-market by slashing post-processing time. By integrating these systems, enterprises can reliably produce high-fidelity tooling and end-use parts that meet stringent engineering tolerances and premium aesthetic standards.