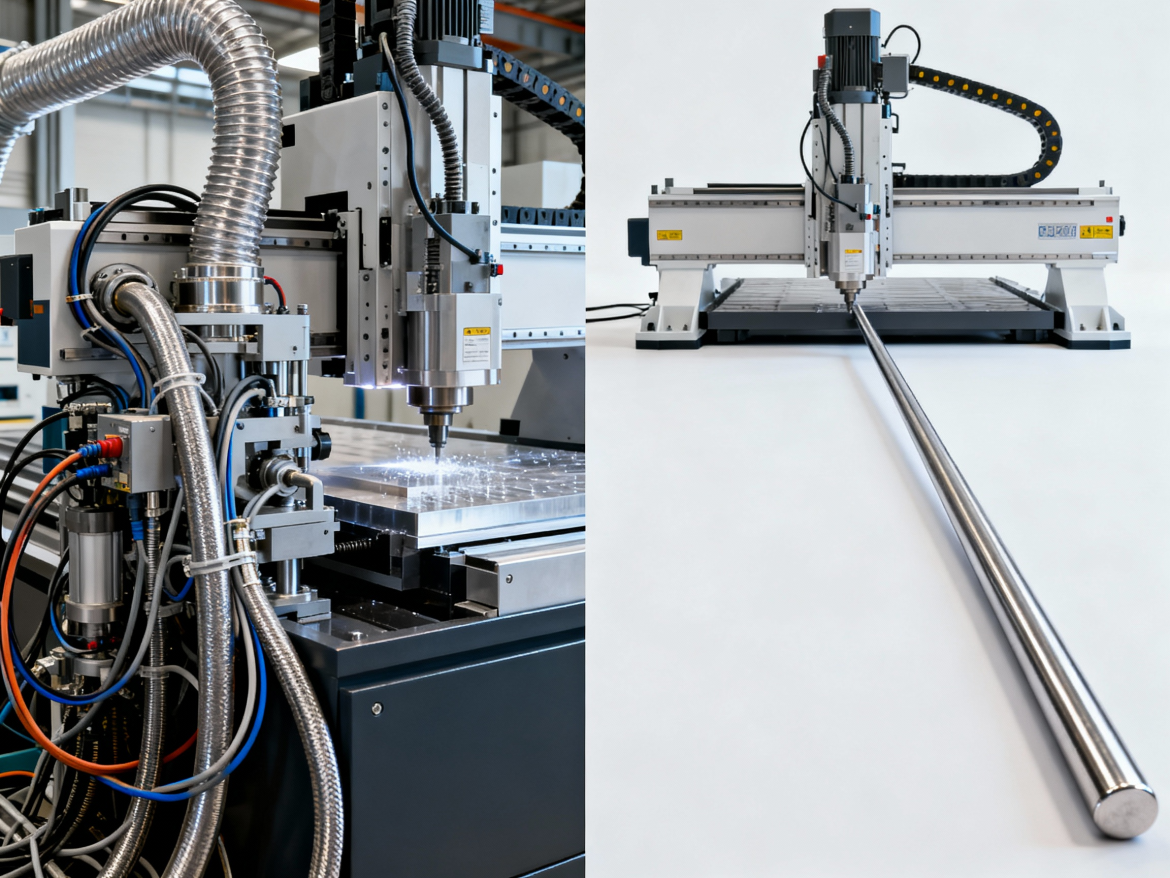

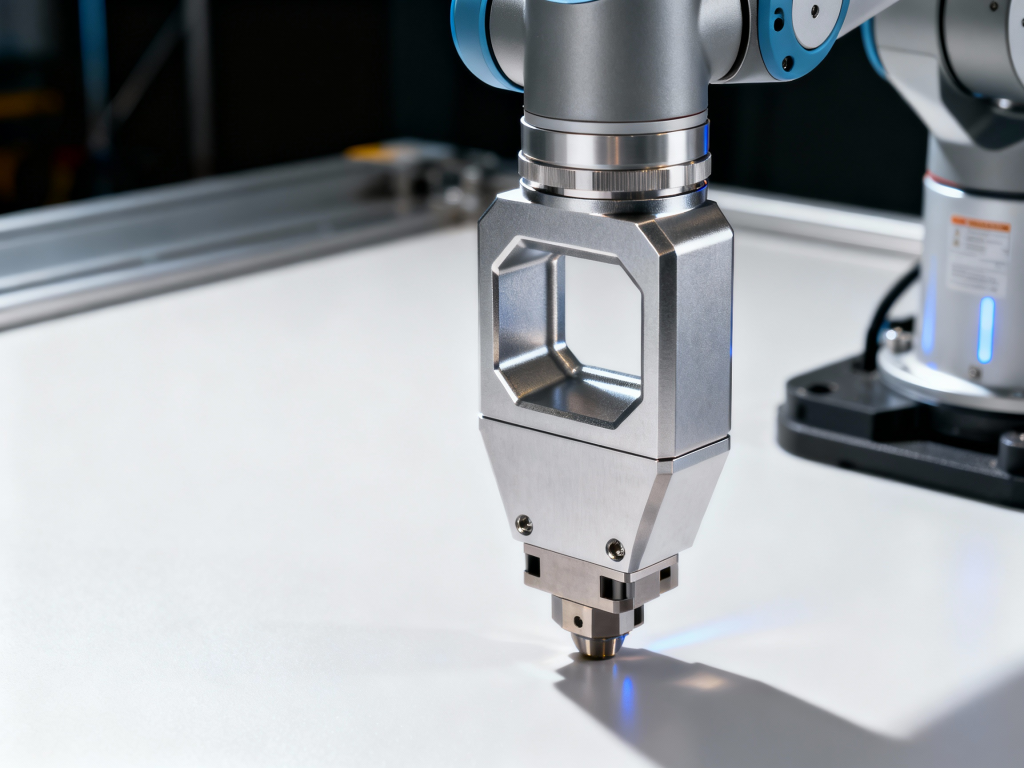

Custom CNC milling serves as the fundamental manufacturing process for robotic end-effectors, directly addressing the engineering conflict between structural rigidity and low inertia. In high-speed automation, every gram of weight at the distal end of a robot arm multiplies the torque required from the motors. By selectively removing material from high-strength alloy blocks—a technique known as pocketing—manufacturers can reduce component weight by up to 60% while maintaining the stiffness required to handle heavy payloads without deflection. This subtractive precision ensures that grippers and sensors maintain the exact center-of-gravity needed for high-speed acceleration, preventing motor strain and ensuring repeatable alignment in automated assembly lines.

Engineering Lightweight Rigidity Through Strategic Pocketing and Alloy Selection

Reducing the moment of inertia in robotic wrists requires a calculated approach to material removal and alloy selection, balancing mass reduction with structural integrity to prevent operational failure.

Optimizing the Payload-to-Weight Ratio in Dynamic Systems

The efficiency of a robotic system is defined by its payload-to-weight ratio. Engineers calculate the moment of inertia to determine where mass can be safely removed without compromising the end-effector’s ability to resist deformation under load. Custom CNC milling cost analysis often reveals that while aggressive pocketing increases machine time, the long-term savings in motor wear and energy consumption are substantial. Advanced ribbing patterns, such as Isogrid or Orthogrid structures, are machined into the walls of the component. These triangular or rectangular pockets distribute multi-directional loads more effectively than solid walls, often retaining 90% of the rigidity while removing 60% of the mass. For instance, an end-effector machined from a solid 7075-T6 aluminum block can be pocketed to weigh less than 500g while supporting a 5kg payload, a critical ratio for high-speed pick-and-place operations in electronics manufacturing.

Selecting High-Strength Alloys for Thin-Wall Machining

The choice between 7075-T6 Aluminum and Grade 5 Titanium (Ti-6Al-4V) depends on the specific stiffness-to-density requirements. Custom CNC milling services capable of processing these materials must mitigate stress release during machining. 7075-T6 offers a yield strength of approximately 503 MPa, making it ideal for lightweight grippers. However, for applications requiring higher fatigue resistance, Grade 5 Titanium, with a yield strength of 880 MPa, allows for thinner wall sections (down to 0.5mm) but requires specialized tooling strategies to prevent heat buildup.

Achieving Geometric Perfection and Complex Contouring in Robotic Assemblies

Precision alignment is non-negotiable for end-effectors, as even micron-level deviations can lead to assembly errors or sensor misalignment in automated cells.

Precision Datums and Interface Tolerancing

To ensure interchangeability, end-effectors rely on precision-machined datums and dowel holes. CNC milling service manufacturers must achieve H7 tolerances (typically +0.010/0 mm) on mounting holes to guarantee repeatable positioning when grippers are swapped. Geometric Dimensioning and Tolerancing (GD&T) standards usually dictate flatness and parallelism of flange mating surfaces to be within 0.02mm. This level of precision ensures that the Tool Center Point (TCP) remains true relative to the robot flange. In regions with growing automation sectors, companies searching for custom CNC milling georgia based options or those supporting logistics hubs via custom CNC milling savannah focused supply chains demand these strict adherence protocols to minimize downtime during changeovers.

Evaluating Custom CNC Milling Services for Complex Geometries

Robotic components often feature complex geometries, such as internal pneumatic channels or undercut sensor mounts, which require 5-axis machining. This technology allows the cutting tool to approach the workpiece from virtually any angle, enabling the creation of seamless contours without re-fixturing. This reduces setup errors and ensures superior surface finishes, often achieving Ra 0.8µm or better, which is critical for sterile medical environments or cleanroom applications. Whether sourcing globally or looking for custom CNC milling savannah area support, the ability to machine multiple sides in a single clamping is a key indicator of a supplier’s capability to deliver high-precision robotic parts.

Precision CNC Machining Solutions by Livepoint Tooling

Livepoint Tooling leverages over 23 years of expertise to deliver high-precision CNC manufacturing solutions, specializing in complex robotic components and high-mix, low-volume production.

Delivering Micron-Level Accuracy for Global Industry

Livepoint Tooling operates as a premier manufacturer, adhering to strict international standards such as DIN-2768-1-fine for metals and DIN-2768-1-medium for plastics. Their facility is equipped to handle intricate machining tasks with a tolerance range as tight as 0.005–0.01 mm. This precision is supported by a robust machining stroke capacity of 800–3200 mm, accommodating both small precision gears and large-scale robotic arms. By integrating 3-axis milling, turning, grinding, and EDM capabilities under one roof, Livepoint provides a true “One-Stop Service” that streamlines the transition from rapid prototyping to mass production. Their commitment to quality ensures that every component, whether 7075 aluminum or stainless steel, meets the rigorous demands of the automotive, medical, and automation sectors.

Contact Livepoint Tooling today to engineer your robotic end-effectors with precision CNC milling strategies that deliver the optimal balance of lightweight agility and industrial durability.