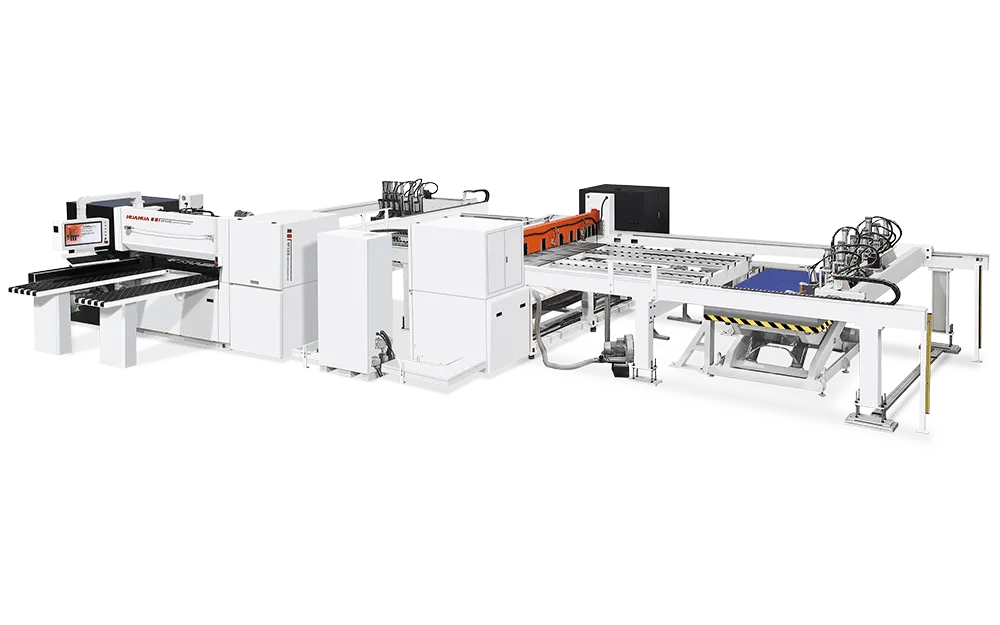

The CNC panel saw is far more than a specialized tool for cutting wood, and HUAHUA CNC, a trusted name in Foshan’s woodworking machinery sector, has engineered theirs to excel across a wide range of materials. With nearly 20 years of industry experience and a dedicated team of experts, their CNC panel saw is designed to adapt to the diverse needs of modern manufacturing, making it a versatile addition to any production line.

Beyond Wood: Cutting a Variety of Materials

Unlike many conventional saws that are limited to wood-based materials, HUAHUA’s CNC panel saw demonstrates exceptional versatility. It effortlessly handles plywood, MDF, and chipboard, and also performs equally well with non-wood materials such as aluminum, plastic, MMPA, and PC boards. This broad material compatibility eliminates the need for multiple specialized machines, saving valuable workshop space and simplifying production workflows—especially beneficial for businesses that handle custom orders involving mixed materials.

User-Friendly Operation and Precision

Ease of operation is another key strength of this CNC panel saw. Its intuitive control system ensures that even operators with limited experience can quickly become proficient, reducing training time and minimizing errors. The precision servo reducer is a critical component, automatically adjusting the cutting height based on the thickness of the panel, maintaining accuracy even at high operating speeds of 4,000 rpm. This level of precision not only ensures clean, accurate cuts but also minimizes material waste, contributing to lower production costs over time.

Conclusion

HUAHUA CNC’s CNC panel saw stands out for its remarkable versatility and user-friendly design, making it an ideal choice for manufacturers looking to expand their processing capabilities. By seamlessly handling a wide range of materials with consistent precision and ease of use, it proves to be a smart investment that can adapt to the ever-changing demands of the manufacturing industry.